Over the past few years there have been plenty of revolutionary developments that are bringing about making waves in the fashion and electronics sectors. It’s critical to stay informed of these new developments and in this article we focus on two of the major manufacturing industries as supply networks adapt to changing needs.

At Source One, we keep a close eye on any changes that may have an effect on sourcing strategies and manufacturing processes. Businesses can then seamlessly adapt their approach in order to remain efficient and competitive by having a firm grasp of industry developments.

Automation and Sustainability in Electronics Manufacturing

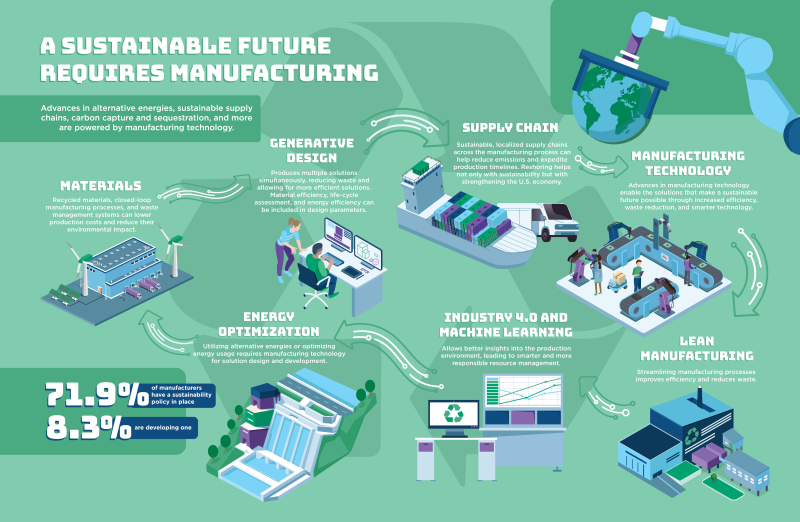

The increasing prevalence of automation in electronics production is one of the most noticeable changes. Thanks to developments in areas such as robotics, AI, and machine learning, manufacturers are discovering new methods to increase efficiency, boost accuracy, and save expenses. Automation solves any potential labor shortages while maintaining a high level of quality by enabling companies to run more consistently and efficiently.

The electronics industry is placing more and more focus on sustainability in addition to automation. While adopting renewable energy sources and cutting emissions are important aspects of this, they are not the only factors at play. Additionally, manufacturers are trying to find methods to use more environmentally friendly materials and reduce e-waste. Sustainability is starting to take precedence, whether it be via recycled parts or materials that may be utilized again after a product reaches the end of its existence.

In addition, there is a growing movement towards products that are more energy-efficient. Electronics that use less energy are in high demand from both consumers and companies, which is pushing manufacturers to use more energy-efficient designs and parts. New possibilities are being created by this trend for companies that can satisfy these demands while still operating efficiently.

Source: McKinsey website

Customization and Ethical Sourcing in Apparel Manufacturing

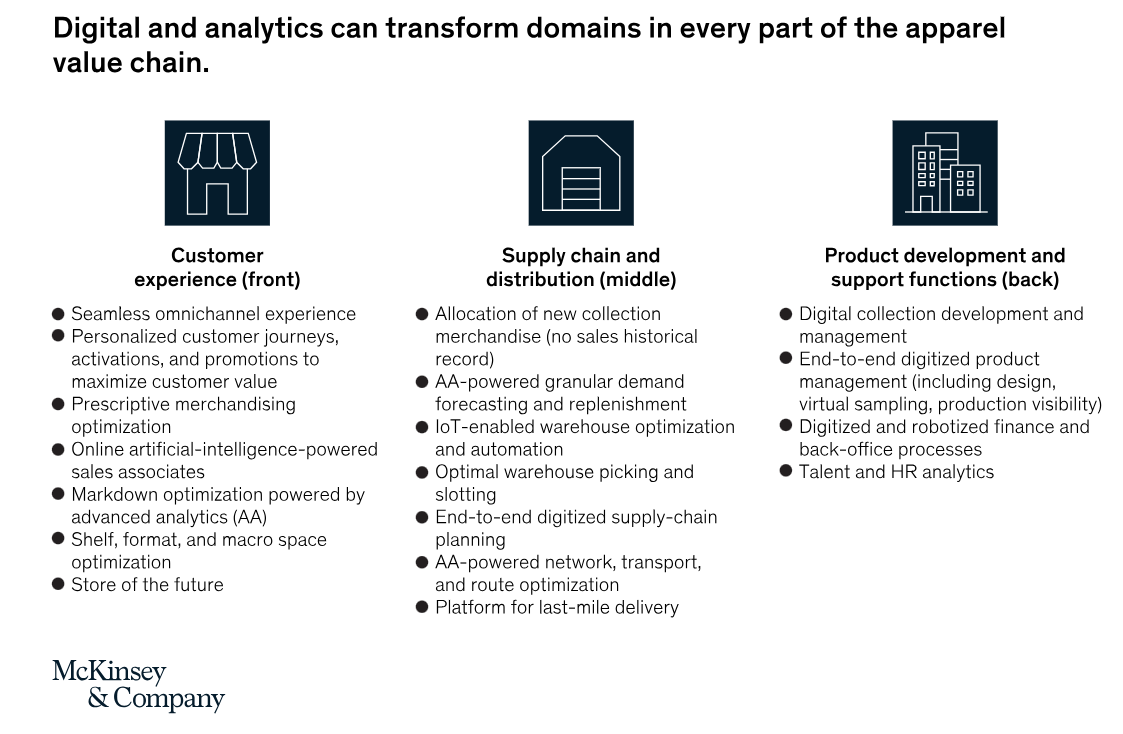

Though trends have always influenced the apparel industry, what we have seen is a greater emphasis on ethical manufacturing and customization. Technological developments in 3D modeling, digital printing, and on-demand manufacturing are enabling clothing companies to provide more individualized products. Manufacturers are adapting by offering flexible manufacturing systems that can handle smaller runs and distinctive designs in response to consumers’ growing need for products that represent their own styles.

But customization is much more than simply aesthetics these days. It is also connected to the larger trend of cutting waste and surplus inventories. Manufacturers may decrease waste and the environmental effect of wasted resources by making garments on demand or in smaller quantities.

Another important trend influencing the manufacture of clothing is ethical sourcing. Nowadays, buyers are increasingly aware of the manufacturing processes and origins of the clothing they purchase. This has forced businesses to examine their supply chains more closely and make sure that environmental and labor regulations are followed. Ethical factors are increasingly important when it comes to sourcing choices, whether it be via the use of environmentally-friendly materials, safe working conditions, or fair wages.

Source: McKinsey website

Supply Chain Agility in Both Sectors

The necessity for supply chain agility is one factor that unites the production of electronics and clothing. Due to the recent revelations about the vulnerability of global supply chains, companies are reconsidering their sourcing and logistical strategies. To prevent bottlenecks and interruptions in the electronics industry, this necessitates diversifying sources and investigating emerging markets. Being able to swiftly adapt to shifting consumer preferences and trends is crucial for the garment industry.

At Source One, we are aware that this transition to a more flexible supply chain calls for a solid grasp of international markets as well as strong relationships with dependable suppliers. We assist businesses in lowering risks and ensuring the resilience of their supply chains by collaborating closely with partners in various geographical areas.

Technology Integration in Manufacturing

Technology integration has begun to play a major role in increasing industrial efficiency, whether it is in electronics or clothing. Manufacturers are improving the efficiency of their operations and the way they address any problems by using data analytics, Internet of Things (IoT) devices, and real-time monitoring systems. Predictive maintenance technology, for example, may assist in locating issues and resolving them before they cause expensive production downtime.

Smart technology is also making its way into the design process in the garment business. Designers and manufacturers are able to visualize and test goods before they are manufactured thanks to virtual prototyping and augmented reality technologies. As a result, lead times are shortened, waste is decreased, and products can be guaranteed to fulfill the required criteria right away.

Finding Manufacturing Trends and Opportunities

Businesses that want to have a competitive advantage must keep up with these new trends as the production of electronics and clothing continues to change. The future of these businesses is being significantly shaped by automation, sustainability, customization, and ethical sourcing. At Source One, we’re dedicated to supporting our clients through these shifts by offering specialized sourcing solutions that take into account both short- and long-term objectives.

Businesses in these industries may not only exceed customer expectations but also set themselves up for future success by concentrating on creating flexible, technologically advanced supply chains.