Our Solutions

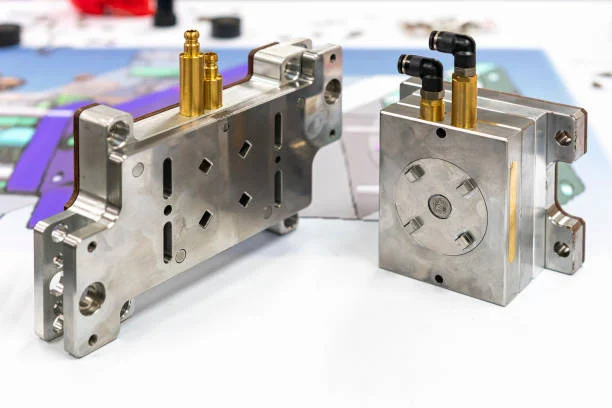

Die Casting

Fabrication

Injection Molding

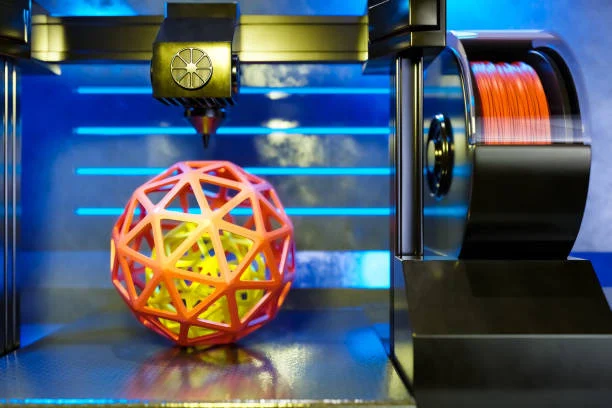

Rapid Prototyping

Casting and Forging

All-inclusive solution

Sourcing

We don’t own factories which keeps us searching for the most cost- effective producers and manufacturers all over Asia. We have developed a specific process for comparing options that includes pricing in addition to quality.

Engineering

Quality Control

The Source One dedication to quality begins before production starts. Each factory is evaluated using our proprietary Field Audit Report. We examine procedures, employee training records, product safety and inspection reports, and ensure employee benefits and labor practices are met in a fair and equitable way before recommending them to our customers. Learn more about our Field Audit Reports.

Sample evaluation

Goods Inspection

Logistics

To round out our comprehensive offering, Source One will coordinate shipments and logistics from the factory to its delivery destination. In our final phase, we can help facilitate payment and outstanding administrative needs. See our Order Tracking Document.

Throughout this seamless process, Source One and your organization can build effective long-term relationships with the low-cost supplier that fits your organizational goals and requirements. We believe in partnership with our customers and collaboration with our vendors. Our goal is to ensure success from the inception of a relationship through the last detail.