Global supply chains today face mounting pressure from all directions. Traditional logistics models, built for efficiency and cost reduction, are struggling to cope with continuous disruptions.

Our teams work closely with businesses whose operations depend on the reliable movement of goods across borders. Whether it’s a delayed shipment, a blocked port, or an unexpected regulation, many factors can disrupt even the most carefully planned logistics networks.

In this article, we draw from our experience supporting global procurement and sourcing teams to explore what it takes to build a truly resilient logistics network. You’ll find practical strategies for increasing agility, reducing risk, and designing smarter systems that can adapt, no matter what comes next.

Why Traditional Logistics Models Are No Longer Sufficient

In recent years, logistics networks have been tested by overlapping global shocks. The aftereffects of COVID-19 continue to linger through port backlogs, container shortages, and limited freight capacity. Meanwhile, new pressures, such as the Red Sea shipping crisis, geopolitical conflicts, and extreme weather events, are creating further instability.

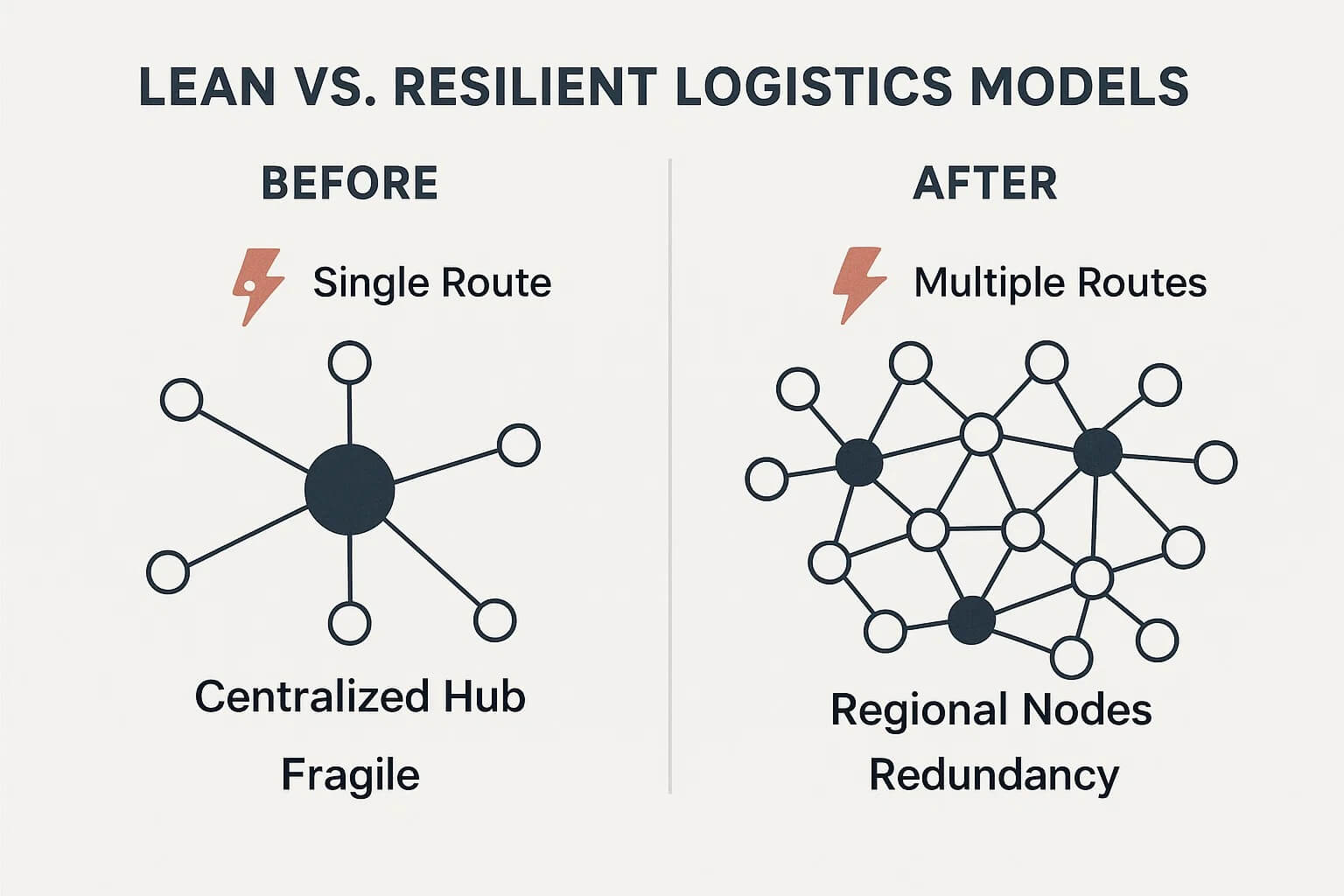

For many companies, logistics systems were built for efficiency, not resilience. Heavy reliance on just-in-time delivery and lowest-cost routing has created networks that look lean on paper but are highly vulnerable in practice. When one supplier, carrier, or route fails, recovery is often slow and costly.

Businesses that previously centralized operations in a single hub or depended on one shipping lane are now re-evaluating these decisions.

What Are the Characteristics of a Resilient Logistics Network?

Visibility and Traceability

A resilient logistics network starts with clear, end-to-end visibility. Real-time tracking tools now allow businesses to monitor container location, port status, and customs clearance in one view. This level of transparency helps procurement teams act quickly when disruptions arise and make better decisions about rerouting or prioritising critical shipments.

More advanced systems also allow visibility beyond tier-one logistics providers. Knowing where a delay is happening in the second or third tier can give you a critical head start in responding.

Flexibility and Redundancy

Flexible networks don’t rely on a single port, mode of transport, or regional hub. Instead, they’re built to adapt. That might mean having the option to shift from sea freight to air for urgent deliveries or maintaining partnerships with multiple 3PLs across different geographies. Regional warehousing strategies also provide a buffer, which allows companies to absorb short-term shocks without halting production.

Companies that empower regional teams to make routing decisions, rather than centralizing everything at headquarters, often recover faster.

Strategic Approaches to Strengthen Logistics Resilience

Supplier and Transport Partner Diversification

Relying on a single freight forwarder or logistics partner can quickly become a bottleneck when things go wrong. Spreading shipments across multiple carriers and regional partners helps reduce this risk. It also offers greater flexibility to shift routes when disruptions occur, whether due to weather, strikes, or geopolitical events.

Diversifying suppliers across both regions and carriers ensures goods can still move even if one location faces delays or restrictions.

Scenario Planning and Risk Mapping

A forward-looking logistics strategy requires identifying weak points before they become failures. Mapping the entire logistics network, such as ports, routes, carriers, and warehouses, helps pinpoint where backups or reroutes would be needed in a crisis.

The Role of Sustainability and Regulation in Logistics Design

ESG Expectations Are Changing Logistics Strategy

Environmental, Social, and Governance (ESG) goals are now influencing how logistics networks are built and managed. More businesses are adopting low-emission freight options, investing in green warehouses, and evaluating the carbon impact of their shipping decisions.

Major retailers and manufacturers are already aligning logistics operations with Scope 3 emissions targets, and this trend is accelerating. Green corridors dedicated to low-carbon shipping routes are also gaining traction globally, supported by public–private initiatives.

Regulatory Pressures Driving Network Redesign

Governments and international bodies are introducing stricter rules around traceability, labour conditions, and environmental impact. Compliance is no longer limited to import/export documentation as it now extends to how goods are moved and who handles them.

New customs regulations, carbon border taxes, and digital compliance requirements (like electronic trade documentation) are prompting companies to redesign parts of their logistics network. For example, the EU’s Carbon Border Adjustment Mechanism (CBAM) will affect transport decisions for emissions-heavy imports into Europe.

Turning Disruption into Opportunity

Resilience in logistics is no longer a competitive advantage, it’s an automatic procedure. In an environment shaped by uncertainty, successful companies are rethinking how goods move, who they rely on, and how quickly they can adapt when conditions shift.

Building flexibility into networks, diversifying transport and sourcing partners, and investing in digital visibility are now core strategies for managing risk. At the same time, environmental and regulatory pressures are pushing logistics from the background into the boardroom.

For teams looking to strengthen their global logistics strategy, Source One offers regionally grounded expertise to help you anticipate challenges and build more agile, future-ready networks.