From forced labor regulations and carbon reporting to shifting technical standards across markets, staying compliant is no longer just a matter of checking boxes. For procurement and sourcing teams operating across borders, it requires constant vigilance, clear internal alignment, and strong supplier oversight.

Global regulations are evolving faster than many companies can adapt. Without a proactive compliance strategy, businesses risk shipment delays, financial penalties, and reputational damage. In this article, we’ll share our practical insights on how to keep pace with regulatory change, from core risk areas to proven strategies for managing compliance across complex, multi-country supply chains.

Why Compliance Is More Complex Than Ever

Today’s compliance environment is fragmented and fast-moving. Each region has its own set of evolving regulations, from Europe’s REACH and CE marking standards to China’s CCC certifications and the U.S. Toxic Substances Control Act (TSCA). Companies sourcing or distributing across multiple markets must track and align with these varied rules, which often conflict or overlap.

Export controls and dual-use regulations add another layer of complexity. Products that are compliant in one country may require additional documentation or testing in another, depending on their classification and end use. This creates challenges not only at the product level, but across the entire supply chain.

Reactive Compliance Carries Major Risks

Compliance is no longer a function that can be addressed retroactively. Delays in updating documentation or failing to monitor changing laws can result in blocked shipments, hefty fines, or even the loss of key customers.

In many cases, companies find out they’re non-compliant only when it’s too late, at customs, in an audit, or after a supplier breach.

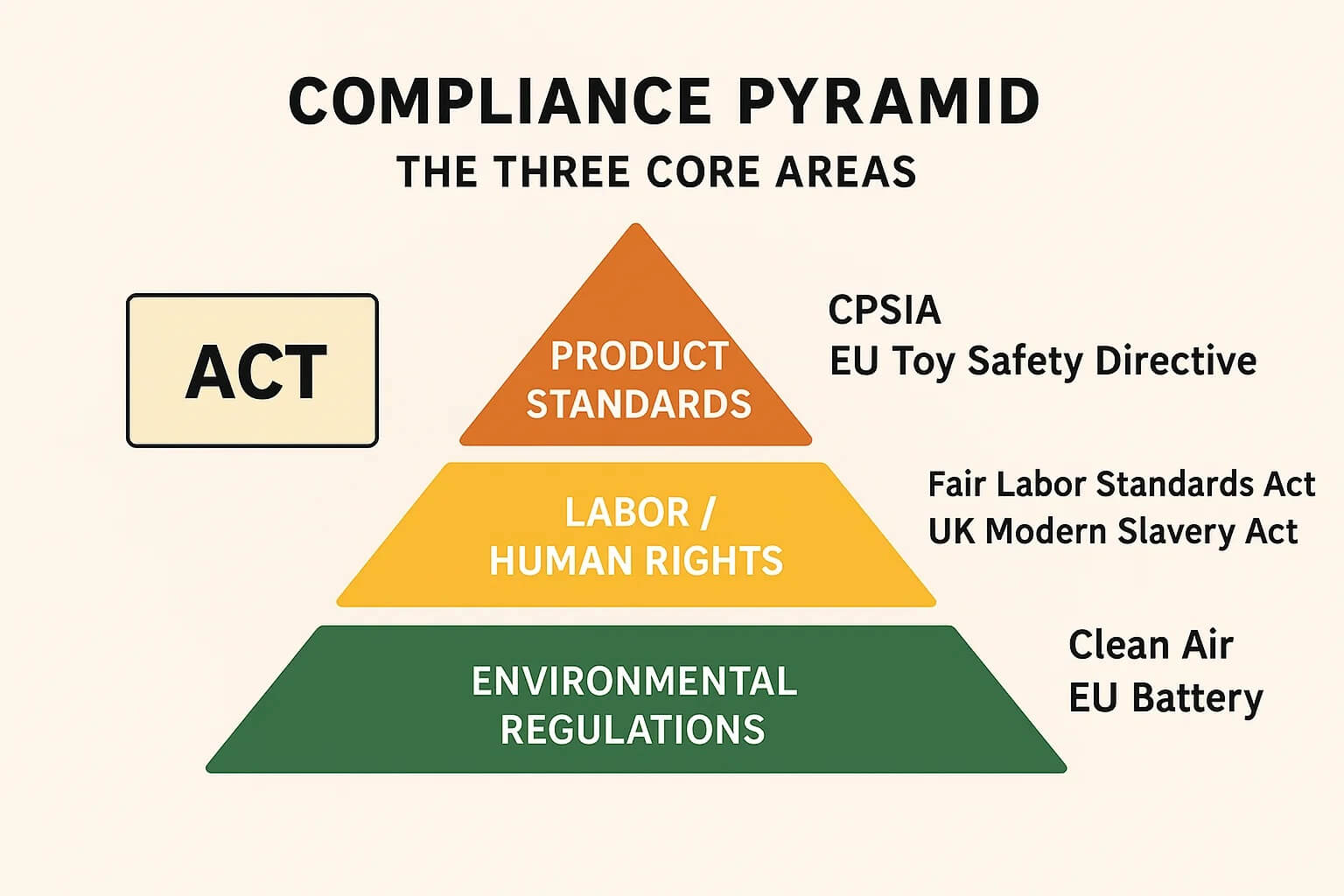

What Are the Core Compliance Areas That Require Active Oversight?

Product Safety and Technical Standards

Regulations governing product safety and performance continue to expand. Depending on the destination market, goods may need to meet specific testing, certification, and labeling requirements. These include CE marking in the EU, FCC compliance in the U.S., RoHS and WEEE directives for electronics, and China’s CCC system. Each standard brings its own documentation and enforcement protocols, often requiring coordination across engineering, procurement, and legal teams.

Misalignment with even one country’s standards can cause costly delays or product recalls, especially in tightly regulated sectors like electronics, automotive, and consumer goods.

Labor, Ethics, and Human Rights

Global supply chains are under growing scrutiny for labor practices. Laws such as Germany’s Supply Chain Due Diligence Act, and Canada’s Fighting Against Forced Labor Act require companies to prove their products are not linked to forced or exploitative labor. Non-compliance can lead to shipment detentions, bans, or reputational damage.

Beyond legal exposure, many buyers and investors now expect alignment with international frameworks like the ILO Conventions and the UN Guiding Principles on Business and Human Rights.

Environmental and Sustainability Regulations

Sustainability is becoming a formal compliance issue. Regulations like the EU’s Carbon Border Adjustment Mechanism (CBAM) and mandatory Scope 3 emissions reporting are pushing companies to account for their environmental footprint, often across tiers of suppliers.

Procurement teams must ensure restricted materials are identified, proper recycling procedures are followed, and upstream suppliers are contributing to ESG goals. This adds a new dimension to supplier evaluation and contract enforcement.

Strategies to Strengthen Standards Compliance Across Your Supply Chain

Establish Clear Compliance Ownership

Effective compliance starts with clear accountability. Procurement, legal, quality assurance, and logistics teams each have a role to play, but without defined ownership, critical tasks can slip through the cracks. Leading companies integrate compliance into supplier onboarding, RFQ processes, and contract terms, which ensures expectations are communicated early and tracked throughout the relationship.

Appointing a cross-functional compliance lead or creating a central task force can help align efforts and improve response times when regulations change.

Conduct Regular Supplier Audits and Assessments

Routine supplier audits are essential, especially in high-risk categories or regions. These reviews should go beyond paperwork, such as verifying real working conditions, certifications, and production practices. Using accredited third-party firms can add objectivity and ensure consistent audit standards.

Standardize and Digitize Documentation

Paper trails no longer cut it in a digital-first compliance environment. Centralized systems that store certifications, testing results, and customs paperwork make it easier to respond to audits or enforcement requests. E-documentation platforms also reduce the risk of missing or outdated records.

Building a Culture of Compliance Across Your Supplier Base

Supplier Training and Capacity Building

Compliance doesn’t begin and end with internal teams, as your suppliers need to understand the expectations too. Offering training on key regulations, documentation processes, and ethical standards helps close knowledge gaps and improves audit outcomes. This is especially important when working with small or regional suppliers who may be unfamiliar with global standards.

Collaborative Compliance Partnerships

Rather than treating compliance as a one-way demand, leading organizations are working with suppliers to solve issues together. Sharing tools, templates, and performance benchmarks fosters trust and encourages long-term improvement. In some cases, buyers and suppliers co-invest in compliance upgrades, such as traceability software or third-party certifications.

These partnerships also support greater transparency, especially when managing shared ESG goals or preparing for new regulations.

Incentivizing Ethical and Sustainable Practices

Compliance metrics are increasingly being included in supplier scorecards and renewal decisions. Suppliers that maintain up-to-date documentation, pass audits, and demonstrate progress on ESG targets should be recognized.

Turning Compliance Into a Source of Competitive Strength

Compliance is about building stronger, more resilient supply chains. Companies that treat regulatory alignment as a core strategy, rather than a last-minute check, are better positioned to enter new markets, respond to disruptions, and meet rising customer and investor expectations.

Investing in visibility, supplier engagement, and real-time compliance tools creates long-term value. It enables faster decision-making, reduces the cost of reactive fixes, and enhances your brand’s reputation for responsibility and transparency.

At Source One, we help businesses implement smart, scalable compliance systems that align with both global regulations and long-term sourcing goals.