In global sourcing, few things cause more frustration than missed deadlines. Your supplier may offer a great price, the quality might be approved, and yet the shipment still shows up late. This delay can create ripple effects across your supply chain, from stockouts to dissatisfied customers.

In reality, manufacturing lead times across Asia are shaped by far more than just the production process. Raw material shortages, congested ports, labour availability, and even rework from failed inspections can all affect your delivery schedule.

In this article, we’ll break down five critical factors that influence lead times in Asian manufacturing, and how experienced sourcing partners like Source One help clients manage these variables to maintain control, reduce risk, and stay competitive.

Raw Material Availability and Procurement Delays

Sourcing Bottlenecks

One of the most common lead time issues stems from delays in securing raw materials. In many Asian markets, especially in industries like electronics, textiles, and packaging, raw materials are either imported or sourced from limited local suppliers. If a key input is unavailable or backordered, production stalls regardless of factory readiness.

Material Substitution and Quality Risks

To avoid missing deadlines, some suppliers may substitute alternative materials without proper approval. While this might save time initially, it often leads to downstream issues including failed inspections or rework, ultimately extending lead time even further.

Experienced sourcing partners like our team help mitigate these risks by confirming material availability during early-stage planning and building in lead time buffers when supply chains are known to be unstable.

Production Capacity and Factory Scheduling

Peak Season Overload

Lead times can extend significantly during peak manufacturing periods. Holidays like Chinese New Year, Thai New Year, Golden Week in China, or Diwali in India often cause factories to shut down for one to two weeks. In the weeks leading up to these closures, production schedules fill quickly, and last-minute orders are often pushed back or declined.

Tier-2 and Tier-3 Supplier Delays

Even when your Tier-1 supplier has production availability, they may be waiting on components from secondary or tertiary vendors. These lower-tier suppliers are not always visible in the supply chain but play a critical role in meeting final delivery deadlines.

Workforce Availability and Labour Conditions

Skilled Labour Shortages

Labour availability plays a major role in determining how quickly a factory can complete production. In regions experiencing high demand or rapid industrial growth, skilled workers may be in short supply. This is particularly true for technical manufacturing sectors such as electronics assembly in Malaysia or tool and die production in India.

When labour is stretched thin, production can slow down or shift quality control responsibilities to less experienced staff, leading to higher error rates and delays.

Compliance with Labour Laws

Labour regulations across Asia vary, but many governments are increasing oversight on worker rights and hours. These protections are essential, yet they can reduce production flexibility during tight deadlines. In countries like Thailand and Vietnam, for example, restrictions on overtime hours mean factories must plan further ahead to meet delivery targets without overworking staff.

Logistics and Port Congestion

Inland Transport and Last-Mile Delays

Even after production is complete, getting goods to the port can introduce unexpected delays. In countries like India and Vietnam, where infrastructure varies widely between urban and rural areas, poor road conditions and limited rail access can slow down cargo movement. Regulatory checkpoints and customs inspections along the way can further extend transit times.

Port Capacity and Global Shipping Pressures

Once at the port, congestion is another critical factor. Popular export hubs such as Ningbo in China, Tanjung Pelepas in Malaysia, or the Port of Veracruz in Mexico regularly experience backlogs. These delays are often tied to global freight cycles, container shortages, or bottlenecks in customs clearance.

Quality Control and Rework Requirements

Inspection Delays

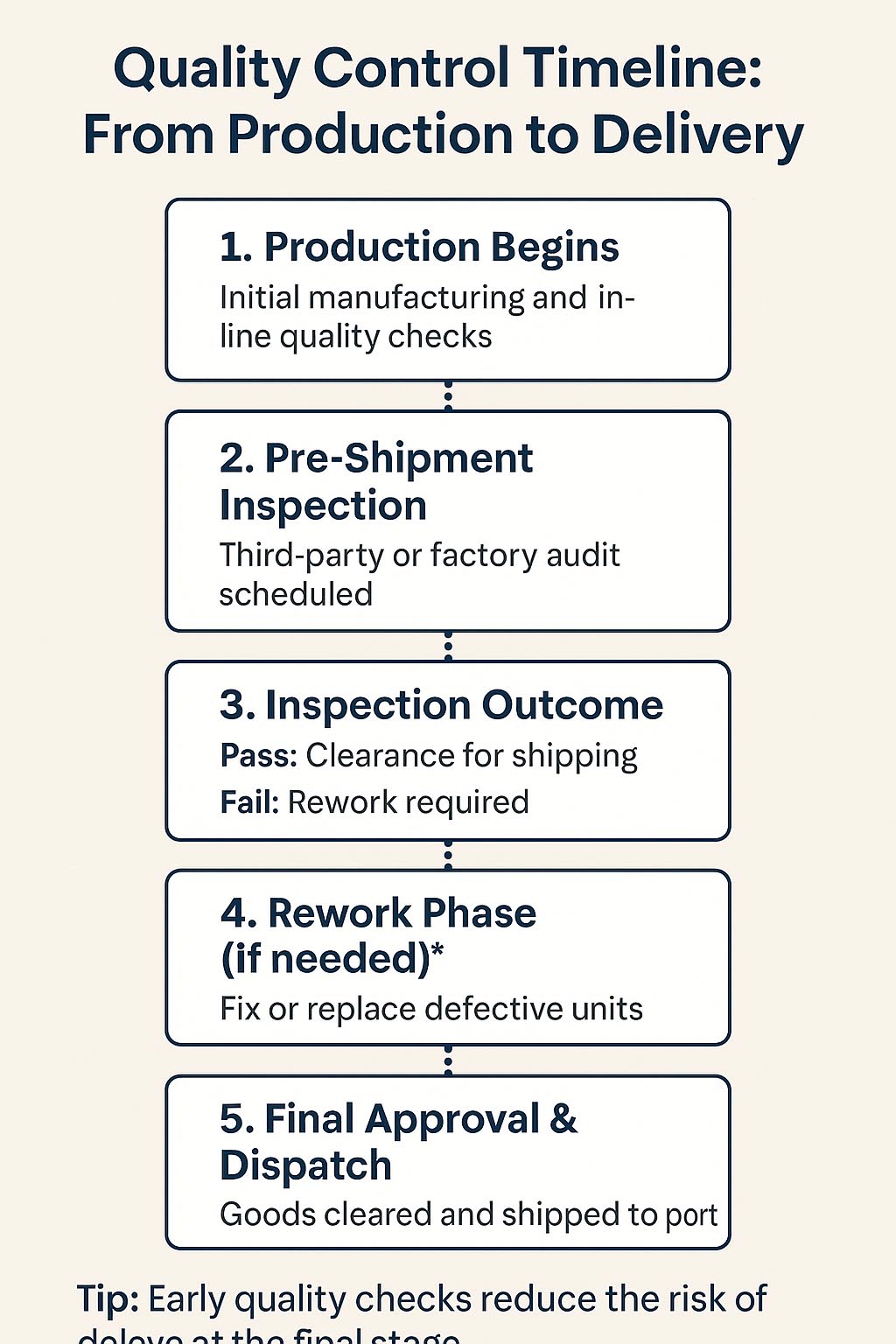

Quality inspections are a vital step before any shipment leaves the factory. However, if inspection windows are missed or third-party auditors are overbooked, this can delay approvals and shipping dates. In markets like China or Thailand, where export volume is high, last-minute inspection requests can push your timeline back by several days.

Scheduling inspections in advance and working with reliable third-party partners is essential for keeping production on track.

Rework and Replacement Timelines

If a batch fails inspection, suppliers may need to rework part or all of the order. This not only adds time but can also disrupt the production schedule of other clients, compounding delays. For instance, replacing a custom moulded plastic component in Vietnam or India could take an additional 5 to 10 days depending on tooling and labour availability.

We integrate quality control early in the process. Our teams conduct in-line checks during production, reducing the likelihood of major rework at the final stage.

Gaining Control Over Lead Times in Asian Manufacturing

Lead times in Asian manufacturing are rarely influenced by a single factor. From upstream material sourcing and factory scheduling to port congestion and inspection delays, the path from order to delivery involves many moving parts. Even when costs and quality are under control, overlooking these factors can lead to unexpected delays and missed opportunities.

Managing these variables effectively requires more than just placing an order. It involves planning around peak seasons, understanding local infrastructure, coordinating inspections, and building in contingency options when things change.

We help global clients navigate these challenges with clear communication, proactive planning, and on-the-ground support. Whether you’re sourcing from India, China, Thailand, Mexico, or anywhere in between, our regional teams help ensure your products move efficiently and arrive on time.