Thailand has long been admired for its ceramics, for beauty and tradition, but also for craftsmanship that blends heritage with commercial viability. From hand-painted Benjarong and elegant Celadon to durable stoneware for hospitality, Thai producers offer a diverse mix of artisan skill and scalable manufacturing, all at competitive costs.

For businesses sourcing tableware, home décor, or branded collections, Thailand presents strong advantages: flexible minimum order quantities, custom design potential, and production capabilities that suit both boutique retail and large-volume wholesale. In this guide, we’ll walk you through Thailand’s ceramics strengths, share our experience on how to choose the right type of supplier, and what to look for when aligning your sourcing strategy with the right manufacturer.

Understanding Thailand’s Ceramics Heritage & Market Strengths

Thailand’s ceramics industry is rooted in centuries of cultural artistry, with modern adaptations that meet global quality standards. This rare combination of design, skill, and production versatility makes it especially attractive for brands that value both aesthetic and function.

Iconic Styles with Global Appeal

Thailand’s rich ceramic traditions offer a depth of style not easily found elsewhere:

Benjarong: Traditionally reserved for Thai royalty, these multi-colored porcelain pieces often feature intricate gold detailing. Today, Benjarong is being reimagined for high-end tableware and luxury décor.

Celadon: Originating from Chiang Mai, Celadon is known for its soft green glaze and subtle crackle finish. It’s widely used in contemporary homeware collections, appreciated for both visual texture and everyday durability.

Sangkhalok: Dating back to the Sukhothai period, Sangkhalok ceramics feature hand-carved motifs and earthy glazes, which is ideal for boutique interiors or heritage-inspired brands.

Modern workshops and manufacturers across Thailand are blending these traditional techniques with contemporary forms, making them suitable for export markets across retail, hospitality, and design sectors.

Quality Craftsmanship at Competitive Prices

Thailand’s ceramic producers are known for:

- Skilled handwork from artisans trained in multi-generational studios

- Reliable firing techniques and glaze consistency, suitable for both ornamental and food-safe products

- Pricing that balances premium quality with affordability, which is particularly attractive compared to European makers or overburdened Chinese suppliers

Artisan Studios vs. Export-Ready Factories

Not all ceramic manufacturers in Thailand operate the same way. Depending on your product, order volume, and design goals, choosing the right type of supplier is just as important as selecting the product itself.

Artisan Studios

These are typically small-scale, family-run workshops or independent makers, especially common in Chiang Mai, Lampang, and Sukhothai. What sets them apart?

- Lower MOQs: Often 50–300 units, ideal for boutique brands or test runs

- High-touch design collaboration: Open to prototyping, small-batch glaze testing, or hand-detailed finishes

- Longer lead times: Expect 8–12 weeks depending on season and complexity

- Higher unit costs, but strong perceived value, especially in Western markets

Perfect for retailers or hospitality venues seeking unique, handcrafted pieces with a story.

Export-Ready Factories

On the other end of the spectrum are larger ceramics factories focused on bulk production. These are often located around Bangkok, Samut Sakhon, or Nakhon Pathom, and they are close to logistics hubs and ports.

Key traits include:

- Higher MOQs, typically 1,000+ units per SKU

- Fast turnaround with automated forming, glazing, and firing processes

- Custom molding capabilities, particularly for tableware sets, hotel-ware, or branded white-label collections

- Certifications like ISO 9001, BSCI, or food-safe compliance (e.g., FDA, LFGB)

If your business relies on predictable volume and tight deadlines, factories like these offer both cost savings and reliability.

We help clients assess which model best suits their goals, or when a hybrid approach (artisan for hero products, factories for core lines) makes sense.

Matching Supplier Types to Your Business Needs

Knowing your product is one thing. Knowing what kind of supplier suits your business model? That’s where smart sourcing begins. Whether you’re a boutique retailer, a wholesale distributor, or part of the hospitality sector, Thailand offers options, but each comes with different trade-offs.

What’s the Best Fit for You?

Business Type | Ideal Supplier | What to Prioritize |

Retail | Artisan Studio | Uniqueness, small batches, hands-on collaboration |

Wholesale | Export-Ready Factory | Scale, speed, price consistency |

Hospitality | Hybrid or Factory | Custom branding, durability, mid-range MOQ |

Let’s break it down:

Retail brands: benefit from partnering with artisan studios for standout SKUs; think hand-glazed tea sets or limited-edition décor items. Higher unit costs are offset by the product story and design differentiation.

Wholesalers: typically prioritise price-per-unit, lead time, and reliability. Factories that offer consistent quality across thousands of units are ideal here.

Hospitality clients: such as boutique hotels or restaurants, often sit in the middle. They may want custom-printed logos, durable stoneware for daily use, or mixed-size orders across different products.

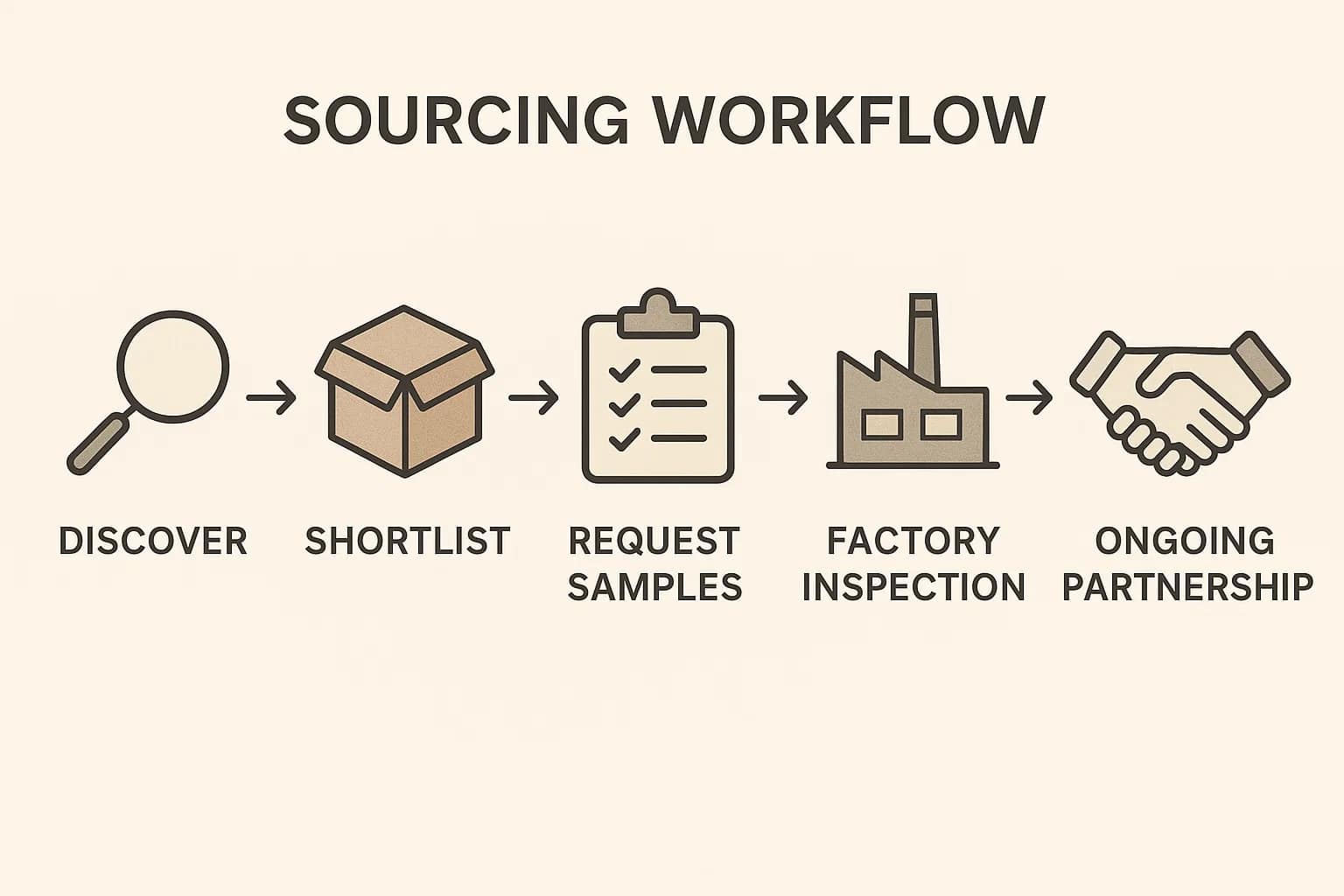

How to Find and Vet Thai Ceramic Manufacturers

With so many options across Thailand, from quiet Chiang Mai studios to industrial clusters near Bangkok, the challenge is finding the right one. The most successful sourcing partnerships start with informed discovery and careful vetting.

Where to Start Looking

There’s no single path to finding a great ceramics supplier, but here are some smart entry points:

Trade shows: Bangkok Ceramics Fair, Thailand International Furniture Fair (TIFF), or STYLE Bangkok all feature artisan and export-ready manufacturers.

Online platforms: Look beyond Alibaba. ThaiTrade.com (by the Department of International Trade Promotion) or niche sourcing sites can offer more curated results.

Industry referrals: Ask other buyers or use agents like Source One with local knowledge and vetted factory networks.

Visiting in person isn’t always feasible, but virtual tours, production videos, and third-party inspection reports are excellent substitutes.

Vetting for Fit, Not Just Capability

A supplier might look good on paper, but can they meet your business goals?

Run through a simple checklist:

- Can they show past export experience in your category?

- Do sample pieces reflect consistent glaze, finish, and form?

- What are their packaging standards, especially for fragile or international shipping?

- Are they open to minor tweaks or only working from standard catalogs?

At Source One, we help our clients build lasting relationships with producers that align on values, reliability, and growth potential. Our QC teams and sourcing experts on the ground in Thailand streamline the process and reduce the risk.