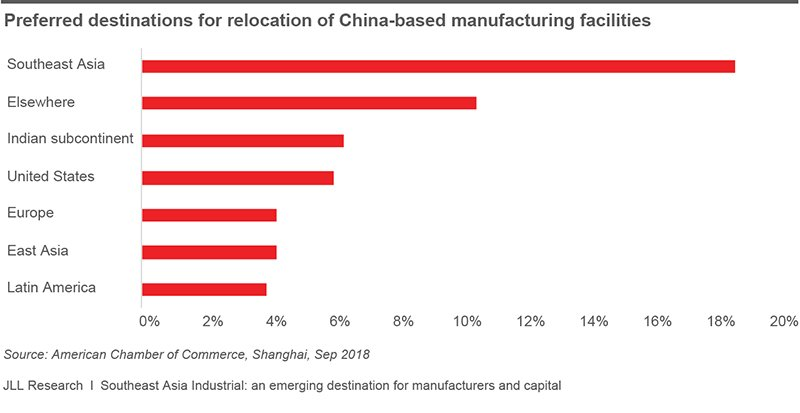

China is a manufacturing powerhouse that has long been sought after by the international garment industry. The country has been a popular option for cut and sew operations because of its robust infrastructure, highly qualified labor pool, and cost benefits. Nonetheless, a lot of companies are looking at other options due to growing labor expenses and changing geopolitical conditions. Southeast Asia is becoming a formidable competitor with more affordable prices, developing expertise, and enhanced manufacturing capacities. But is it a competitive cut and sew manufacturing alternative to China?

Accessed from: JLL Website

Availability and Labor Costs in Both Regions

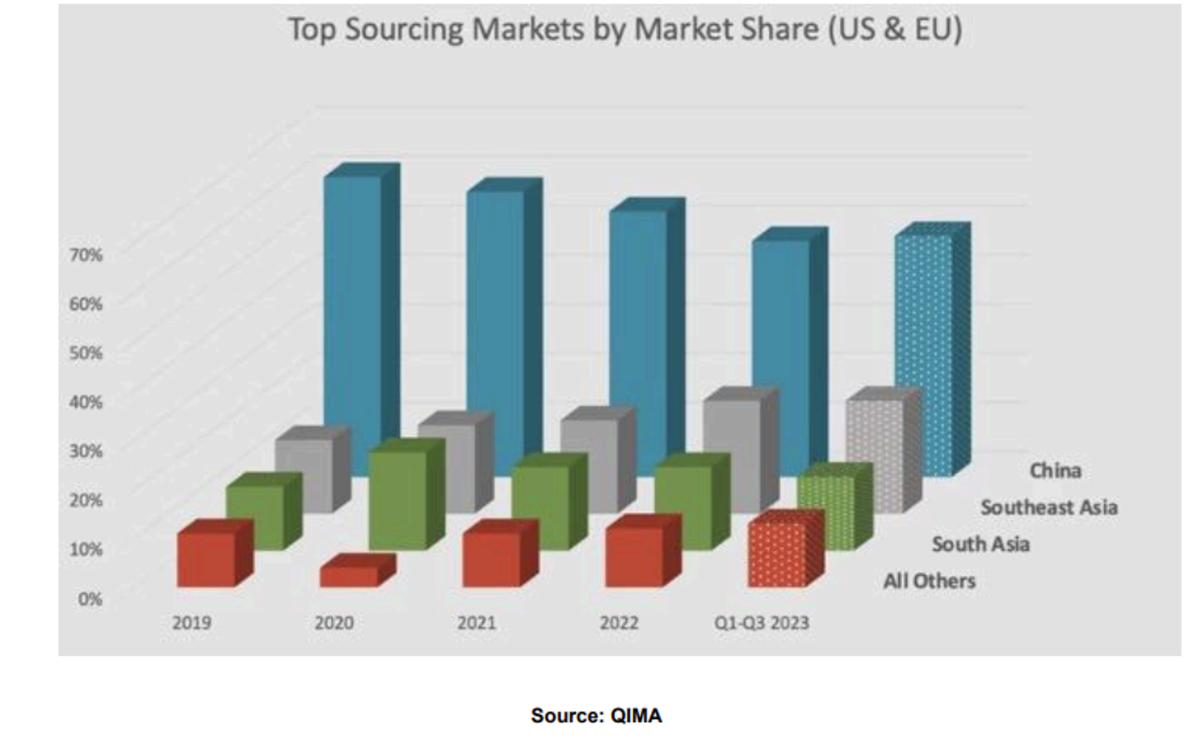

Southeast Asia is being researched by businesses primarily because of its labor cost advantage. Vietnam, Cambodia, and Indonesia are appealing possibilities for corporations looking to cut expenses since these countries offer wages that are much more economical than those in China. Vietnam’s expanding apparel sector and growing infrastructure have helped it rise to prominence in the area.

Young, expanding labor forces in these nations are likewise keen to work in manufacturing. A consistent supply of labor is made available by this expanding worker pool, reducing the likelihood of delays brought about by labor shortages. However, as more companies invest in technology and training, Southeast Asia is playing catch up to China’s manufacturing hubs, which in various instances still have superior knowledge and efficiency.

Production Capabilities and Infrastructure

An important factor to consider when thinking about cut and sew options is infrastructure. Southeast Asia is making significant advancements in supply chain and logistics infrastructure, though China has spent decades developing such networks. To better enable large-scale manufacturing, Vietnam, Thailand, and Malaysia, for instance, have upgraded their ports, energy sources, and transportation networks.

Even though certain Southeast Asian nations may still be growing in comparison to China’s well-oiled machine, the area is becoming more and more appealing due to recent advances. These days, a lot of manufacturers can provide competitively priced, high-quality output. Governments in Southeast Asia are additionally making trade agreements and foreign investments that promote the expansion of manufacturing as a high priority, which facilitates the streamlining of procedures for international businesses.

Market Access and Trade Agreements

The advantageous trade agreements of Southeast Asia are a major contributing factor to its increasing appeal. Numerous agreements that provide better access to global markets benefit the area. For instance, Vietnam now has more options to export products without tariffs or with lower charges thanks to its membership in the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the EU-Vietnam Free Trade Agreement (EVFTA).

Businesses are able to provide items at more competitive pricing due to these trade agreements, especially in areas like North America and Europe. Southeast Asia’s trade network clearly offers benefits above China, where tariffs may be a cause for concern for businesses aiming to enter certain markets.

Accessed from: ASEAN Exchanges website

The Value of Quality and Expertise

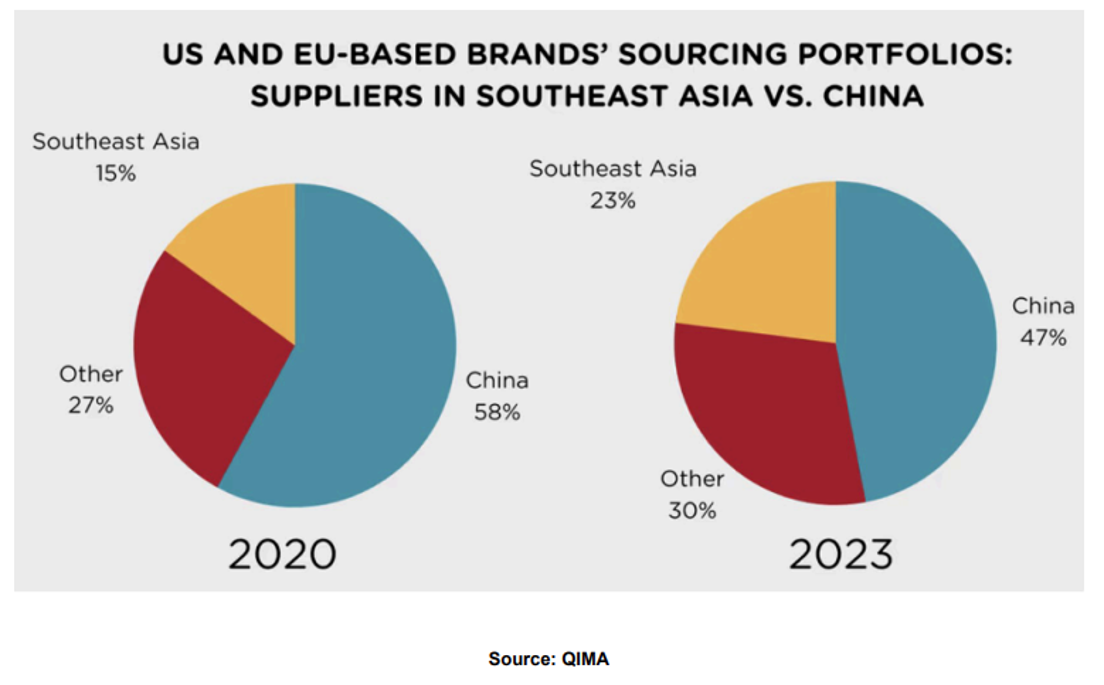

Maintaining the same degree of quality and competence is a recurring consideration when production is moved away from China. The country has decades of experience behind it to hone its procedures and build a highly competent labor force that can produce large quantities. That being said, Southeast Asia is rapidly expanding its capabilities, especially in Vietnam, which is becoming recognized for producing high-quality garments.

China may still be a superior choice in certain situations for businesses with more sophisticated designs or specific demands due to its extensive expertise. However, the disparity between the two areas is narrowing as Southeast Asian businesses keep up investment levels in technology, quality assurance, and worker development.

Lead Times and Proximity

One issue that companies may have when sourcing from Southeast Asia is the possibility of extended lead times. Improvements in Southeast Asia’s infrastructure are beginning to lessen production and delivery delays, even as China’s well-established logistics network enables speedier production and delivery. For instance, lead times from Vietnam are steadily reducing as producers simplify their processes and transportation infrastructure becomes better.

The greater distance from Southeast Asia may nevertheless result in somewhat longer delivery times than China for companies exporting to markets in Europe or the US. But as global supply chains evolve, a lot of businesses are discovering that the advantages of having access to advantageous trade agreements and reduced labor costs often exceed these minor delays.

Diversification and Risk Management in the Apparel Industry

Many organizations have made it a goal to diversify their supply networks in recent years. Being too dependent on one area of the world for manufacturing, like China, might leave you vulnerable, particularly in times of disruption like trade disputes or global health emergencies. By broadening their sourcing possibilities to include Southeast Asia, businesses may mitigate risk and enhance supply chain stability.

The apparel industry’s growing popularity in Southeast Asia provides companies with an option that might help them balance their sourcing strategy. Many businesses are taking a hybrid approach, using China for more complicated manufacturing while outsourcing simpler cut-and-sew operations to Vietnam or Cambodia, instead of transferring all of their production out of China.

Accessed from: ASEAN Exchanges website

Identifying Cut and Sew Manufacturing Opportunities

Is cut-and-sew production in Southeast Asia a viable alternative for China, then? The fact is that it depends on the particular requirements of the company. Southeast Asia has a lot to offer businesses that seek to lower labor costs, diversify supply chains, and take advantage of advantageous trade agreements. Numerous businesses find the area to be an attractive alternative due to its expanding infrastructure, rising production quality, and vast labor pool.

But it’s crucial to take into account things like lead times, manufacturing complexity, and product quality standards. There is an excellent opportunity for cost savings and long-term stability for companies in Southeast Asia that are prepared to make investments in fostering connections and streamlining processes. At Source One, we collaborate closely with companies to assess their sourcing options and create strategies that support their objectives, guaranteeing that every part of the supply chain is set up for success.