Asia has firmly established itself as a global manufacturing powerhouse, allowing small firms an unmatched opportunity to save on prices and access into a vast selection of goods and suppliers. For many of us, sourcing from Asia offers a strategic advantage that may revolutionize our company operations. Even so, it is essential to approach it with careful preparation, comprehensive risk management, and a good awareness of the local context.

Digital Tools for Modern Sourcing in Asia

Gone are the days when only major corporations could handle the challenges of international procurement. Today, digital technologies have leveled the playing field, enabling us to access a variety of information, connect with suppliers, and even compare pricing, all at our fingertips.

Modern communication and translation applications play a key role in addressing linguistic and cultural barriers. Tools like real-time translation applications and video conferencing platforms assure that we can connect effectively with suppliers, negotiate terms transparently, and establish the type of strong, trust-based relationships that are vital in the Asian market.

Direct vs. Indirect Sourcing in Asia

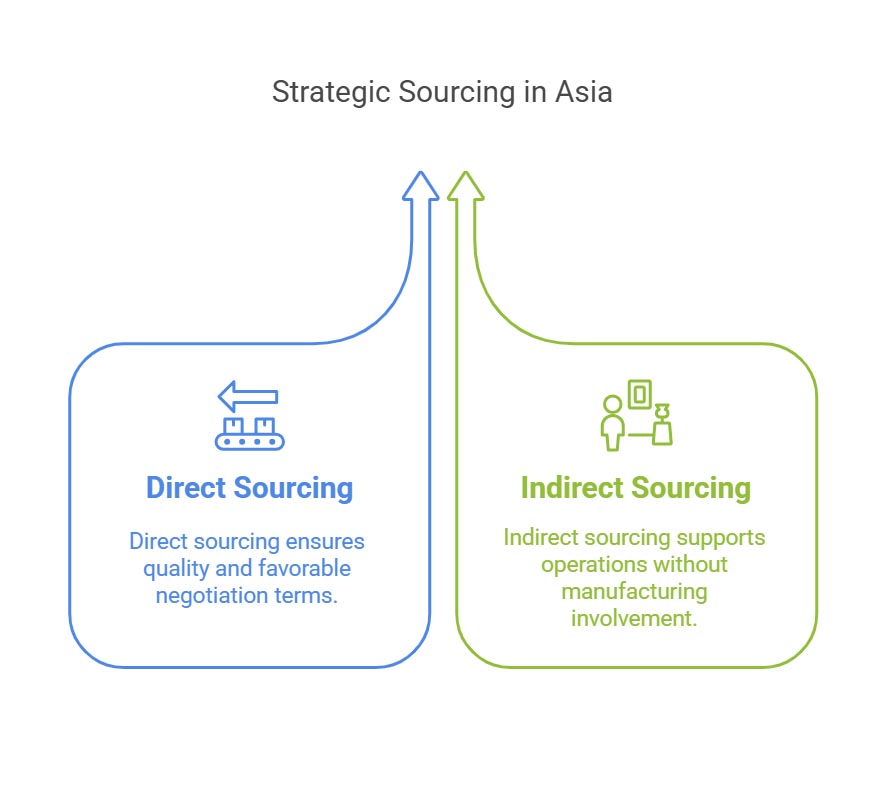

Understanding the distinction between direct and indirect sourcing is key. Direct sourcing involves procuring items that are vital to our core activities, such as raw materials or components utilized in manufacturing. Indirect sourcing, on the other hand, pertains to products that support company operations but are not directly related to manufacturing, such as office supplies or maintenance services.

By identifying and concentrating on direct sourcing for our manufacturing requirements, we can better monitor quality, negotiate more advantageous terms, and guarantee that our supply chain stays resilient and efficient.

Navigating Risks and Avoiding Common Pitfalls in Sourcing from Asia

Sourcing from Asia has various advantages, but it also comes with its distinct set of obstacles. One of the key difficulties is managing the complexity of global supply networks. The sheer number of stages between raw material sourcing and completed product may often hide the quality and ethics of the process. To address this, we must develop explicit standards and quality control methods. Third-party inspection services may also be essential in evaluating product quality before distribution.

Hidden expenditures, such as unanticipated storage fees or variable transport charges, may rapidly erase the financial advantages of international sourcing. Negotiating clear pricing and taking into account all conceivable expenses—from transportation and import tariffs to storage costs at ports or warehouses—are crucial measures in defending our bottom line.

Supply chain transparency is another crucial topic. It’s crucial to guarantee that our suppliers adhere to ethical standards and comply with both international and local legislation. This involves performing frequent supplier audits, setting clear ethical standards, and fostering long-term relationships with suppliers renowned for their sustainable practices.

Cultural and communication obstacles might also pose substantial problems. Different cultural expectations and communication styles may lead to incorrect assumptions that undermine negotiations and operational efficiency.

Legal and Compliance Considerations in Sourcing from Asia

When working with suppliers in Asia, managing international trade rules and regulations is crucial. It’s not only about obtaining a fair price; it’s also about ensuring that contracts are legally robust, intellectual property is safeguarded, and all import/export requirements are followed. We work to establish contracts that preserve our clients’ interests and assure compliance with local and international regulations.

Optimizing Inventory and Managing Costs

Effective inventory management is another cornerstone of a successful sourcing strategy. By properly regulating our inventory levels, we can prevent expensive stockouts or the strain of excess inventory. This ties up less funds and also decreases storage expenses. Negotiating reasonable prices while keeping an eye on hidden expenses demands a full awareness of all factors involved: from manufacturing and shipping to payment terms and storage fees.

Supply chain risk management (SCRM) is crucial in today’s turbulent industry. Natural disasters, political upheaval, or even an unexpected supplier failure may interrupt our supply chain. By proactively identifying these risks and creating comprehensive mitigation plans, we bolster our resilience and assure continuity in our operations.

Building Sustainable Partnerships Through Cultural Awareness

At the core of effective sourcing in Asia is the creation of resilient supplier relationships. Building these collaborations isn’t just about negotiating contracts, it means investing in long-term, mutually beneficial relationships. In Asia, commerce is typically founded on trust and personal ties. A relationship-focused strategy, where frequent contact is required, follow-through on pledges, and even occasional trips to suppliers, may make a major impact.

Understanding cultural nuances is crucial. For instance, many Asian corporate cultures favor indirect communication and put a high priority on relationship development. By adapting communication styles such as being respectful of local traditions, awareness of cultural holidays, and being mindful of local business etiquette, we can develop deeper relationships and assure easier operations.

Scaling Operations and Diversifying Your Supplier Base

Diversifying supplier bases mitigates risks associated with over-reliance on a single source and also boosts the ability to satisfy expanding demand. Exploring alternate suppliers across various locations in Asia may help decrease the effect of future interruptions and enhance overall supply chain resilience.

While global sourcing delivers tremendous economic reductions, we must equally assess the benefits of domestic sourcing. In many circumstances, buying raw materials locally may lead to speedier delivery times, decreased shipping costs, and simpler compliance with domestic laws. This hybrid approach may give a balanced strategy, integrating the benefits of both global and local sources.

Leveraging Automation for Enhanced Efficiency

Automation is another trend that small firms may leverage to boost productivity and decrease expenses. From AI-powered inspection systems that boost quality control to robots and real-time tracking systems that expedite production and inventory management, adopting automation may give a major competitive advantage.

Choosing the Right Asia Sourcing Strategy

Selecting the right sourcing strategy in Asia relies on a comprehensive review of many critical factors:

Cost Considerations: It’s vital to examine the overall cost of sourcing, including the manufacturing cost along with transportation, import tariffs, and hidden charges.

Quality Requirements: Determining the quality standards necessary for products and ensuring that vendors can satisfy those levels is crucial.

Lead Times: The desired delivery timelines must correspond with manufacturing requirements. Ensuring that suppliers can dependably satisfy lead times is a significant element.

Sustainability Goals: With increased focus on ethical and sustainable operations, we assess suppliers based on their environmental and social responsibility practices.

Risk Tolerance: Finally, recognizing your risk tolerance and diversifying your supply base accordingly can prevent possible interruptions.

At Source One, our strategy is founded on cooperation and long-term relationships. We have found that by working closely with our suppliers and stakeholders, we can negotiate the complexity of the Asian sourcing environment efficiently. Whether it’s by embracing digital innovation, maintaining regulatory compliance, or recognizing cultural subtleties, our objective is to assist small companies to establish resilient, efficient, and sustainable supply chains.